Making one’s own practice or match ammunition is a rewarding and cost-saving way to enjoy the shooting sports. In the case of precision rifle ammunition, a more accurate cartridge developed for a specific rifle will theoretically perform better than factory-produced ammunition that must work well in a wide range of rifles.

When the goal of handloading is to make match grade ammunition, attention to details — such as sorting cases by head stamp and tracking the number of times a case has been fired — helps to make consistent loads, which in turn makes the finished cartridge shoot more accurately. An absolutely necessary tool for a project like this is a reloading manual that includes charge weights for specific bullets, maximum case length, as well as cartridge overall length dimensions.

In my opinion, two important goals for cartridge assembly are safety first, and then accuracy. To succeed, reloaders must know which components to use together. While safe loads that produce large groups are undesirable, accurate loads that produce unsafe pressures must always be avoided.

To achieve this, there are many data sources. Smokeless powder manufacturers supply data for their propellants. Bullet makers supply data for their projectiles. Still more data can be found online. Where do you start?

For more than a century, Lyman Products Corp. has been compiling and publishing reloading data, and their manuals are — in my opinion — one of the best independent data sources.

The Source

The 51st Edition is the newest Lyman Reloading Handbook. Lyman bought Ideal Reloading in the early 20th century and retained the existing numbering sequence. Number 27 was the first Lyman-Ideal Handbook. Beginning with number 41 (about 1957), the Ideal name was dropped.

Lyman also publishes several specialty handbooks such as the Long Range Precision Rifle Reloading Handbook, The AR Reloading Handbook, 2nd Edition, the Lyman Pistol & Revolver Handbook, Third Edition and the, Cast Bullet Handbook, 4th Edition. The newest Shotshell Reloading Handbook, 6th Edition was released at SHOT Show 2025. As an avid shotshell reloader, I was pleased to see data for many of the newer hulls and powders that came out after the 5th Edition (2007). There are fewer sources of shotshell data than metallic cartridge data.

Behind the Curtain

When I was invited to visit Lyman Products Corp. and tour the ballistics laboratory to see the procedures and equipment used to test and develop load data, I jumped at the chance. This assignment, even with the two-hour drive from New Hampshire to Connecticut, felt like a day at the range rather than a work day!

In recent decades, many new cartridges have been developed: the data for those cartridges will likely appear in one of the specialty handbooks a few years before publication in the Lyman Reloading Handbook.

Published load data are developed under the supervision of Tom Griffin, an engineer who has worked at Lyman for over 40 years. Tom’s first job at Lyman was as the test shooter for the 46th edition of the Lyman Reloading Handbook. He now edits all the Lyman handbooks.

The AR Reloading Handbook has several sections on topics such as the differences between the 5.56 MM NATO and .223 Remington cartridges, AR-15 gas system lengths and, of interest to many in 2025, there is the Handloading for Suppressed Firearms section. The manual includes load data for almost every chambering for AR-15 type rifles, including the now-popular carbines chambered in 9mm.

The 51st Edition of the Lyman Reloading Handbook includes in-depth articles on topics such as case preparation, primers, powders and bullet types, as well as detailed information on the handloading process.

The Long Range Precision Rifle Reloading Handbook, has plenty of information on PRS Shooting, reticles and external ballistics. The newly released Shotshell Reloading Handbook, 6th Edition has dozens of illustrations to help with shell identification and how to tell if a fired shell is still safe to reload. All Lyman books have articles on proper propellant selection as well as data showing the maximum case length, trim to length and cartridge overall length.

The Process

Reloading used cartridge cases is perfectly safe. However, Lyman develops their load data using brand new cases. New, unfired cases ensure proper calibration of the pressure meter. Cases are sized, and bullets are seated on a Lyman All-American 8 Turret Press using Lyman dies. Each powder charge is weighed on a Lyman scale. Powder charge increments can vary based on the case size. Most handgun loads are developed in one-tenth grain increments, while loads for larger rifle cartridges are typically developed in one-half grain increments. Lyman keeps detailed records for all loads they work up.

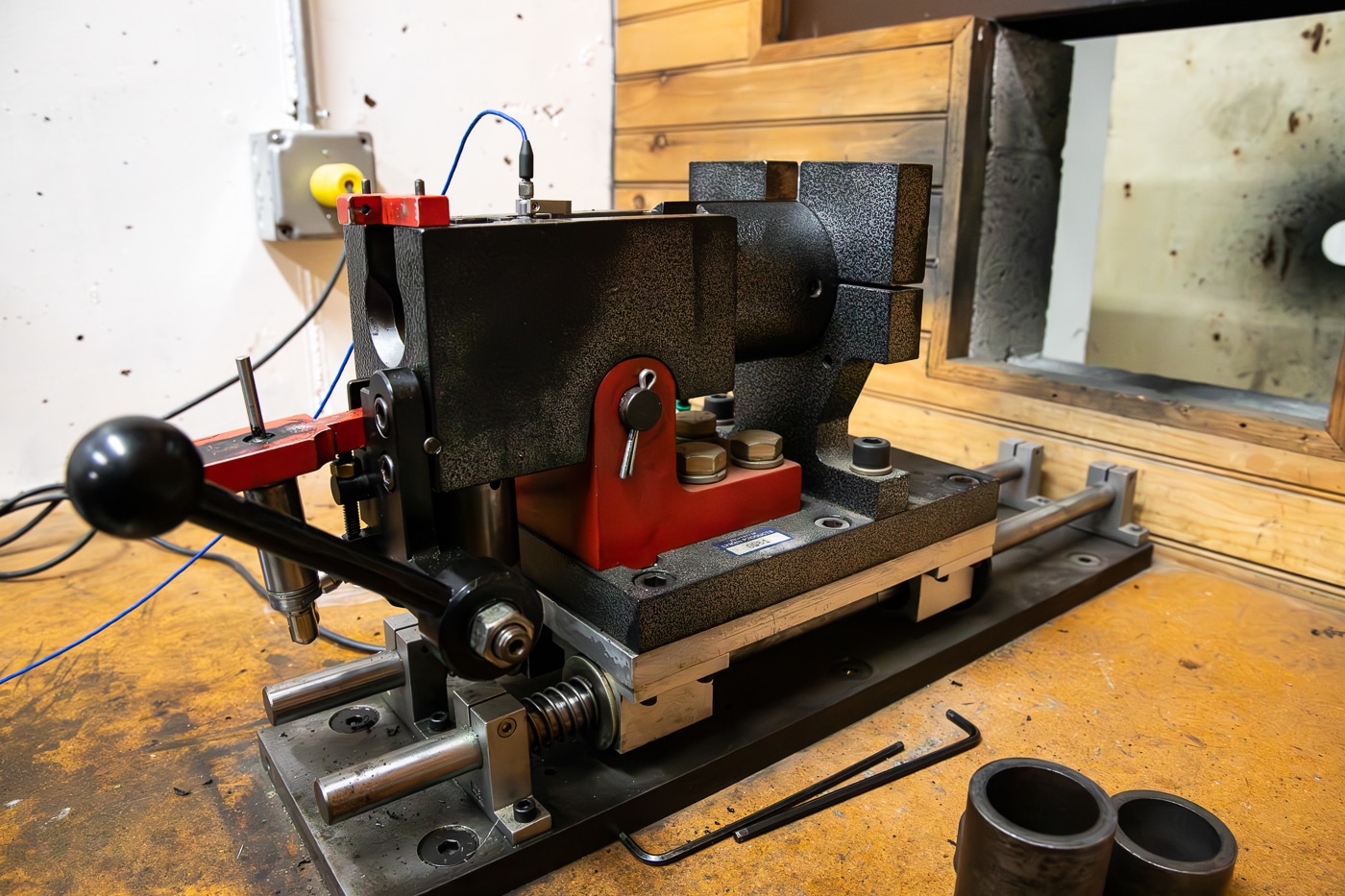

When a “test shooter” produces a cartridge, the process is very clinical. The primer, powder charge, bullet and brand of case are recorded. The cartridge is then placed into a pressure barrel, which is in a fixture that is connected to a device that records the pressure in pounds per square inch (PSI). The “test shooter” then exits the area where the fixture is and discharges the cartridge remotely. An Oehler 35P chronograph measures velocity, the first screen is 10 feet in front of the muzzle and the second twenty feet from the muzzle.

The use of a pressure barrel allows the generated PSI to be measured using modern equipment. Older data (that is still included in the manuals) was measured using copper units of pressure (CUP) but all new data is measured in PSI. It is now hard to get copper crush cylinders, so the system became obsolete. Each published load shows which unit of measurement was used.

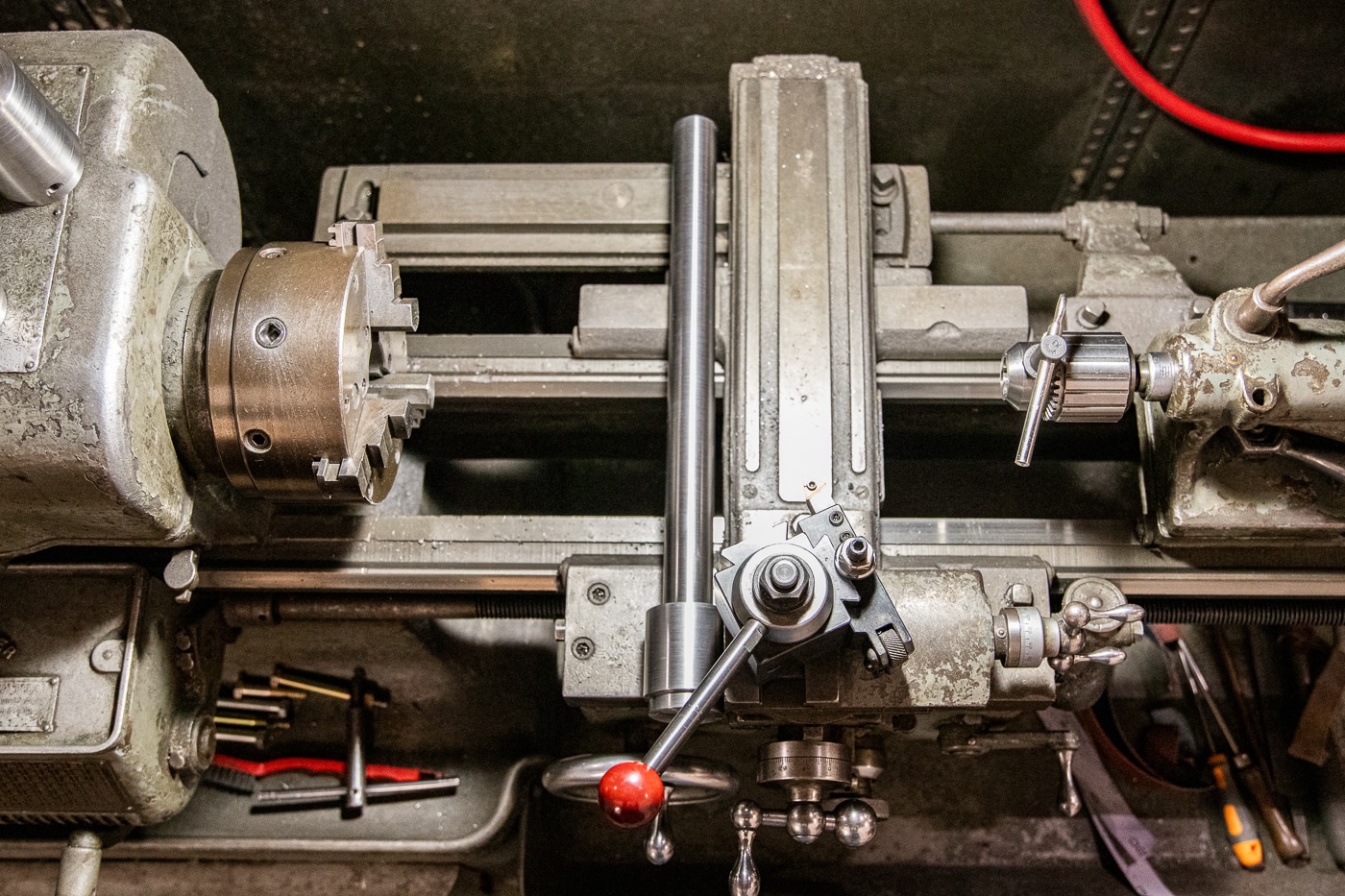

The pressure barrels are caliber-specific and the proper length for the caliber being tested. They are made in Lyman’s Middletown, Connecticut facility. Separate barrels are used for .38 Special and .357 Magnum. Similarly, .40 and 10mm also use separate barrels, as do .380 ACP and 9mm. Tom told me this ensures that the pressure and velocity readings are correct and that the published data will be safe to use in an actual firearm.

Loads published in The AR Reloading Handbook are an exception; all of the cartridges were tested in both a pressure barrel and an actual firearm(s) to ensure proper functioning in semi-automatic firearms.

Use of pressure barrels to develop load data removes many variables, such as slight differences in chamber dimensions, gas port sizes or even extractor or ejector tension. Any one of these variables can affect accuracy and pressures.

To further ensure consistency, all testing is done on the indoor range at the Middletown, Connecticut facility. Temperature changes, wind and precipitation can all alter the external ballistic and pressure data. Performing the testing indoors allows these variables to be controlled.

At Lyman Products Corp., nothing is left to chance, and shortcuts are not taken.

Lyman keeps on hand tens of thousands of bullets from pretty much every manufacturer and a huge selection of powders and primers. They also test and publish data for cast lead bullets, which is rare in 2025.

Lyman’s reloading manuals are a valuable resource because the data is developed using components that Lyman does not produce or sell, but has determined to be the best for each caliber.

Conclusion

So, you can clearly see that Lyman takes its responsibilities seriously when it comes to testing loads and providing that info in their reloading manuals. And now that I have gotten to see how it’s all done, I’m even more impressed!

Editor’s Note: Please be sure to check out The Armory Life Forum, where you can comment about our daily articles, as well as just talk guns and gear. Click the “Go To Forum Thread” link below to jump in and discuss this article and much more!

Join the Discussion

Featured in this article

Read the full article here